High-Quality Steel Flanges: Your Key to Industrial Durability and Reliability

Understanding Steel Flanges

What Are Steel Flanges?

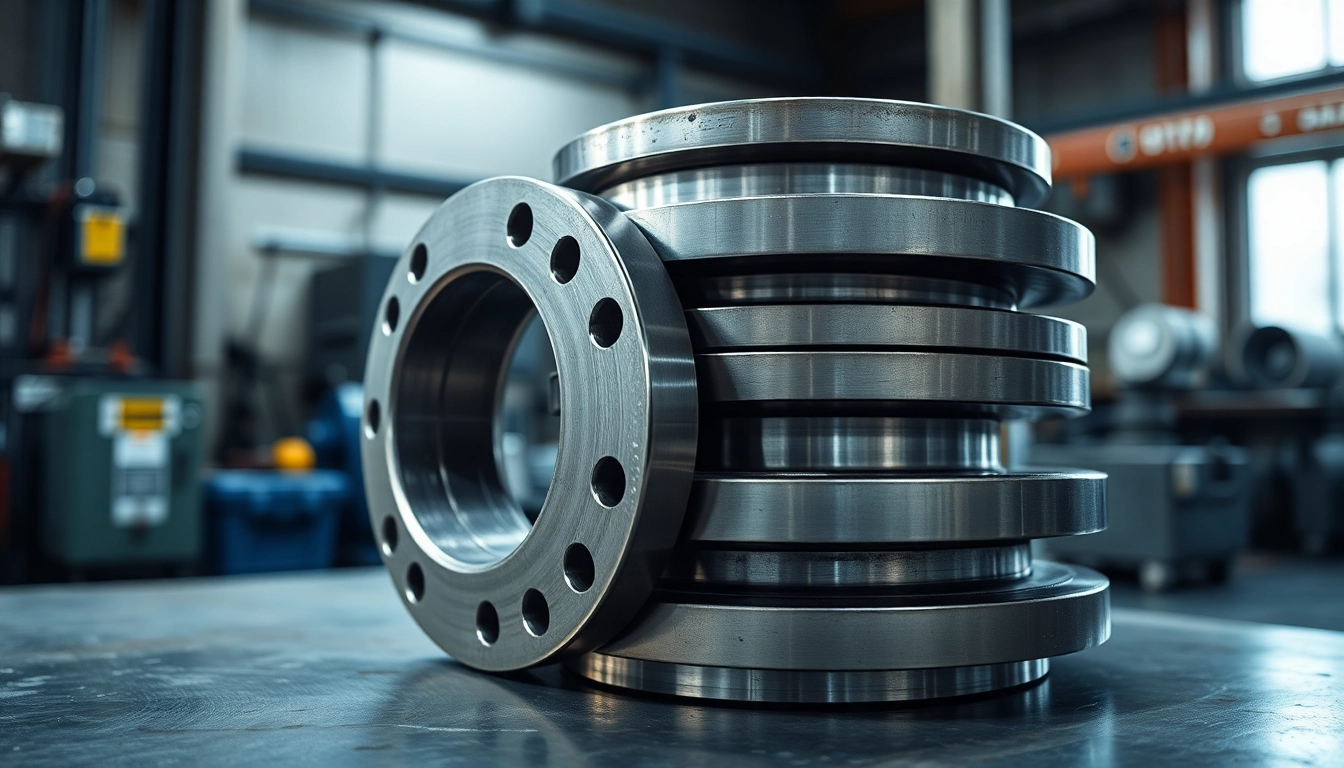

Steel flanges are mechanical components utilized in piping systems to join two sections of pipe or to connect pipes to various equipment, such as valves and pumps. Flanges facilitate the assembly and disassembly of piping systems, allowing for easier maintenance and modification. Fabricated typically from steel, these flanges come with integral sealing surfaces that promote leak-free joints, making them a critical element in many industrial applications.

Flanges are available in various shapes, sizes, and pressure ratings, adapting to the different requirements of plumbing systems in sectors such as oil and gas, chemical processing, and food and beverage. Due to their structural integrity and resistance to high pressure and temperature, steel flanges stand out as a preferred choice. You can explore a comprehensive range of steel flanges, designed to meet the varying needs of diverse industries.

Types of Steel Flanges Available

Steel flanges can be categorized based on their design, manufacturing method, or the application they serve. Understanding the different types is essential for selecting the appropriate flange for your application. Below are some of the most common types:

- Slip-On Flanges: These flanges are designed to slip over the pipe and then are welded to secure them in place. They are versatile and cost-effective, making them widely used in various applications.

- Weld Neck Flanges: Known for their durability, weld neck flanges have a long tapered neck, allowing for a strong and effective weld connection. They are suited for high-pressure applications.

- Socket Weld Flanges: These flanges allow the pipe to be inserted into the body of the flange, facilitating a smooth internal surface. They are commonly used in high-pressure systems.

- Blind Flanges: These flanges are solid and designed to seal off the end of a pipe. Often used for future expansions and testing, blind flanges are crucial in maintaining system integrity.

- Threaded Flanges: With internal threads, these flanges screw onto the corresponding pipe. They are ideal for applications requiring frequent disassembly.

- Lap Joint Flanges: Typically paired with a stub end, lap joint flanges offer flexibility in the assembly and disassembly process, common in low-pressure applications.

Applications of Steel Flanges in Industry

Steel flanges are pivotal components in various industrial applications due to their ability to create robust joints while allowing for maintenance and flexibility. Here are some of the primary sectors where steel flanges are utilized:

- Oil and Gas: In the exploration and production stages, flanges facilitate connections between pipes and equipment, ensuring the safe and efficient transfer of materials.

- Chemical Processing: Flanges are used in chemical processing plants for the transport and storage of substances at varying temperatures and pressures.

- Water Treatment: In municipal water systems, flanges play a vital role in connecting piping that moves water through treatment facilities.

- Power Generation: Power plants utilize steel flanges in their steam, water, and various fuel handling systems, facilitating reliable operation.

- HVAC Systems: Flanges are essential for maintaining the structural integrity of heating, ventilation, and air conditioning systems.

Choosing the Right Steel Flanges

Factors to Consider When Selecting

When selecting steel flanges, several crucial factors can influence your decision and impact the overall performance of your piping system:

- Pressure Ratings: Knowing the pressure requirements of your system is vital. Flanges are rated according to pressure classes, and you should ensure that the flange’s rating matches or exceeds the expected pressure in your application.

- Material Compatibility: Ensure that the flange material is compatible with the fluid or gas it will carry to prevent corrosion and enhance longevity.

- Temperature Ratings: Check the temperature limits of the flange against your operating conditions. Some flanges are designed for high-temperature environments, while others are suited for lower temperatures.

- Size and Dimensions: The flange should match the diameter and specifications of the pipe it is intended for to ensure optimal performance.

- Standards Compliance: Look for flanges that comply with industry standards relevant to your application, such as ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization).

Comparing Materials and Standards

Steel flanges can be manufactured from various materials, each bringing its unique characteristics and advantages. Common materials include:

- Carbon Steel: Offers strength and durability, ideal for high-pressure applications.

- Stainless Steel: Renowned for its corrosion resistance, making it suitable for chemical processing and marine applications.

- Alloy Steel: Incorporates other elements for enhanced mechanical properties, often used in extreme conditions.

- Ductile Iron: Provides excellent strength and impact resistance but is less flexible than steel.

When comparing materials, consider not only the physical and mechanical properties but also the environmental conditions that might impact performance. Adhering to recognized standards such as ASTM (American Society for Testing and Materials) helps ensure quality and performance consistency.

Price vs. Quality: Finding Balance

While it can be tempting to choose flanges based purely on cost, prioritizing quality is essential for safety and longevity. Cheaper options may save money upfront but usually compromise on material integrity or manufacturing standards. The true cost of flanges often extends beyond the purchase price, including potential maintenance, downtime, or safety hazards. Selecting a reputable manufacturer can ensure you obtain quality components that endure throughout system operation, ultimately saving you money and resources in the long run.

Installation and Maintenance of Steel Flanges

Proper Installation Techniques

The proper installation of steel flanges is critical to their performance and longevity. Below are essential techniques to ensure effective installation:

- Surface Preparation: Ensure that the flange surfaces are clean, free of debris, and properly aligned before assembly. Any contamination can lead to leaks.

- Gasket Selection: Choose the correct gasket material suitable for your specific application. Gaskets help to provide a leak-proof seal.

- Tightening Sequence: Follow a specific bolt tightening pattern, such as alternating bolt patterns, which helps evenly distribute the load and prevents warping of the flange.

- Torque Specifications: Use a torque wrench to apply the correct tension on the bolts, as per the manufacturer’s specifications, to avoid over-tightening or under-tightening.

Common Maintenance Practices

Ongoing maintenance is vital to extend the lifespans of steel flanges and ensure system reliability. Regular inspections should include:

- Visual Inspections: Regularly check for signs of leakage, rust, or physical wear.

- Flange Bolts: Inspect bolt tension and retighten when necessary to ensure continued effectiveness of the seal.

- Gasket Replacement: Replace gaskets when they show signs of wear as they degrade faster with high exposure to temperature and pressure.

Signs of Wear and When to Replace

Recognizing the signs of wear in steel flanges is crucial for timely intervention:

- Visible Corrosion: Check for rust or pitting on the flange surfaces, which can reduce structural integrity.

- Fluid Leaks: Any signs of leaks indicate a compromised seal and require immediate replacement of the flange.

- Deformation: Flanges that appear warped or mechanically deformed should be replaced before leading to further issues in the system.

Innovations in Steel Flange Manufacturing

Emerging Technologies in Production

The manufacturing of steel flanges has seen significant advancements due to emerging technologies. Techniques such as precision casting, advanced welding methods, and computer-aided design (CAD) are enhancing the manufacturing process:

- CAD and Simulation Software: Enables precise engineering of flanges for specific applications, resulting in optimized performance and reduced waste.

- Robotic Welding: Increases accuracy in flange production, allowing for consistent quality and tighter tolerances.

- Quality Assurance Technologies: Advanced non-destructive testing techniques, like ultrasonics and radiography, ensure each flange meets safety and quality standards before distribution.

Sustainability Practices in Manufacturing

As the manufacturing sector moves towards sustainable practices, steel flange production is no exception. Key sustainability efforts include:

- Recycled Materials: Utilizing recycled steel in flange manufacturing reduces the overall environmental impact and conserves natural resources.

- Energy Efficiency: Implementing energy-efficient manufacturing processes minimizes energy consumption and carbon emissions during production.

- Reduction of Waste: Innovations in production technology aim to optimize material usage, reducing scrap and waste generated during manufacturing.

The Future of Steel Flanges in Construction

The role of steel flanges in construction continues to evolve as industry demands shift. With rising requires for high-performance materials and eco-friendly practices, the future holds:

- Smart Flanges: Sensor technology integrated into flanges for real-time monitoring can improve maintenance schedules and operational safety.

- Customization: Greater demand for customized components tailored to specific applications will drive design innovations and specialized manufacturing.

- Increased Collaboration: Suppliers and manufacturers will likely engage in collaborative efforts to create robust, comprehensive solutions that encompass entire systems rather than isolated components.

Measuring Performance and Quality of Steel Flanges

Key Performance Metrics to Monitor

Understanding how to measure the performance of steel flanges involves examining several key metrics:

- Yield Strength: The maximum stress that a material can withstand while still returning to its original shape.

- Tensile Strength: Indicates the maximum stress before failure, ensuring the flange will hold under operating conditions.

- Fatigue Strength: Evaluates the flange’s endurance under cyclic loading, crucial for applications that experience fluctuating pressures.

Industry Standards for Quality Assurance

Quality assurance in steel flanges is reinforced by adherence to industry standards. Major industries institute comprehensive guidelines to ensure safety and performance, including:

- ASME B16.5: Governs the dimensions and tolerances for wrought flanges, providing a framework for manufacturers and users.

- ASTM A105: Defines standards for carbon steel flanges, ensuring consistent quality and performance.

- ISO 9001: Certification that indicates a commitment to quality management principles in manufacturing processes.

Real-world Examples of Flange Performance

Instances across various industries provide notable examples of flange performance:

- Oil Rig Applications: High-quality weld neck flanges used in offshore oil rigs withstand extreme conditions, providing secure connections under high pressure and corrosive environments.

- Chemical Plants: Stainless steel flanges designed for chemical processing offer impressive resistance, enabling safe handling of reactive substances.

- Water Infrastructure: Ductile iron flanges used in municipal water systems can handle high flow rates while providing durability against environmental factors.

Leave a Reply