Enhancing Efficiency: The Becker Vacuum Pump for Industrial Applications

Understanding Becker Vacuum Pumps

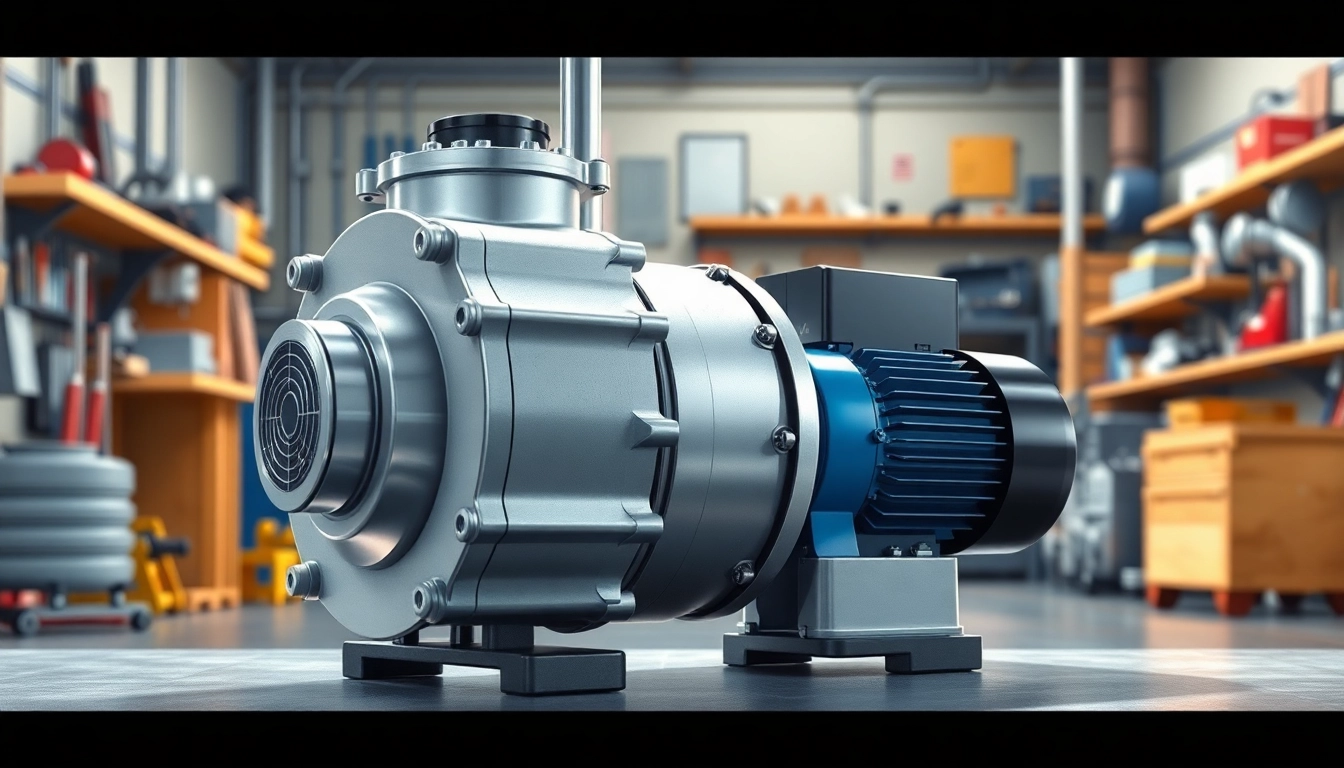

Becker vacuum pumps are renowned for their reliability and efficiency across various industrial applications. These pumps play a critical role in several processes, from food packaging to manufacturing. Understanding the intricacies of Becker vacuum pumps can help businesses optimize operations and enhance productivity. Within this article, we delve deep into what it means to utilize a Becker vacuum pump, spotlighting their features, applications, benefits, and future trends.

What is a Becker Vacuum Pump?

A Becker vacuum pump is a high-performance device designed to create a vacuum by removing air or gas from a contained space. Originating from Germany, Becker has over 140 years of experience in developing and manufacturing these industrial vacuum solutions. The pumps are engineered using advanced technology, which provides users with high efficiency, durability, and environmental sustainability.

Key Features of Becker Vacuum Pumps

Becker vacuum pumps are distinguished by several key features:

- Robust Design: Built to withstand harsh environments while delivering consistent performance.

- Energy Efficiency: Designed to minimize energy consumption without sacrificing output.

- Low Maintenance: The pumps are engineered for longevity and often require less maintenance compared to their competitors.

- Versatile Applications: Suitable for various industries, including food processing, woodworking, and chemical manufacturing.

- Oil-free Operation: Many Becker pumps are oil-less, providing clean and eco-friendly operation.

Types of Becker Vacuum Pumps

Becker offers a diverse range of vacuum pumps to cater to different industrial needs. The main types include:

- Rotary Vane Vacuum Pumps: These are popular for their reliability and efficiency, functioning on the principle of rotating vanes within a cylindrical chamber.

- Oil-lubricated Pumps: Designed for high workload and heavy-duty operations, these pumps utilize oil for lubrication, contributing to smoother operation.

- Dry Pumps: Ideal for applications requiring a clean environment, such as pharmaceuticals and food processing.

- Regenerative Blowers: Used where high flow rates and pressure are necessary, often in pneumatic conveying applications.

Applications of Becker Vacuum Pumps

Becker vacuum pumps find applications across a multitude of industries due to their reliability and versatility.

Industries Utilizing Becker Vacuum Pumps

Several sectors leverage Becker vacuum pumps for their operational processes:

- Food and Beverage: Used in packaging and processing to create vacuum-sealed products that last longer.

- Manufacturing: Essential for molding, forming, and other processes that require vacuum conditions.

- Woodworking: Applied in veneer presses and wood laminating to remove air and ensure clean finishes.

- Pharmaceuticals: Critical in processes that require sterile environments and precise control of vacuum levels.

Common Tasks Performed with Vacuum Pumps

The tasks performed by Becker vacuum pumps include various applications:

- *Evacuation:* Removing air or gas from containers, essential in packaging.

- *Holding:* Creating maintained positive pressure to secure items during processes.

- *Drying:* Accelerating drying processes by removing moisture.

- *Molding:* Assisting in shaping materials by removal of air under pressure.

Case Studies of Successful Implementation

Becker vacuum pumps have led to significant improvements in numerous organizations. For example, a packaging company utilizing Becker rotary vane pumps improved its operational efficiency by 25%, leading to increased throughput and reduced energy costs. Similarly, a pharmaceutical manufacturer reported significant reductions in product contamination rates attributed to the use of oil-free Becker pumps.

Benefits of Becker Vacuum Pumps

Understanding the benefits of Becker vacuum pumps can assist businesses in making informed purchasing decisions.

Efficiency and Reliability

Becker vacuum pumps are synonymous with efficiency, capable of achieving desired vacuum levels swiftly. Their reliable operation minimizes downtime, allowing for continuous production and better overall efficiency in numerous applications.

Cost-Effectiveness Over Time

Though the initial investment for Becker vacuum pumps might be higher, their longevity and low maintenance requirements ultimately lead to lower total costs. Businesses can expect a significant return on investment as maintenance costs diminish over time.

Maintenance Tips for Longevity

Maintaining Becker vacuum pumps is vital for optimal performance:

- Regular Inspections: Conduct frequent checks for leaks, unusual noises, or vibrations.

- Changing Filters: Keep filters clean and replace them periodically to ensure efficient operation.

- Lubrication: For oil-lubricated models, ensure oil levels are maintained and changed as per manufacturer guidelines.

Choosing the Right Becker Vacuum Pump

Selecting the appropriate vacuum pump is crucial for optimizing performance and investment. There are several considerations to account for.

Factors to Consider When Selecting a Pump

When selecting a Becker vacuum pump, consider the following factors:

- *Application Requirements:* Identify what your specific needs are—be it pressure, vacuum level, or flow rate.

- *Operating Environment:* Determine whether the pump needs to be oil-free or can operate in harsher environments.

- *Budget Constraints:* Evaluate the total cost of ownership, taking into account initial purchase price and ongoing maintenance costs.

Comparative Analysis of Models

Conducting a comparative analysis of different Becker models can provide insights into which pump best meets operational needs. Models like the DV Series offer efficient, dry operation while the VK Series delivers robust performance under high loads. Clients can assess specifications to ensure fit with operational requirements.

Where to Purchase Becker Vacuum Pumps

Becker pumps can be purchased from various authorized distributors, online retailers, and through direct sales from Bosch or Becker’s own website. It’s advisable to choose reputable sellers who provide proper support and service plans.

Future of Becker Vacuum Pumps

As industries evolve, so too does the technology surrounding vacuum pumps. Becker is at the forefront of these advancements, continuously innovating to meet changing demands.

Innovations in Vacuum Pump Technology

The future of Becker vacuum pumps looks promising with ongoing innovations. Developments in energy-efficient models and smart technology integration are paving the way for enhanced control systems that monitor efficiency and performance in real-time.

Environmental Considerations

As environmental regulations tighten, Becker’s commitment to producing oil-free and low-energy consumption pumps aligns perfectly with sustainability goals. These environmentally friendly options are becoming critical in industries keen on reducing their carbon footprint.

Trends Impacting the Vacuum Pump Industry

The vacuum pump industry is poised to witness significant changes influenced by technology, automation, and demand for cleaner energy sources. Becker’s proactive approach in adapting to these trends positions them as a leader ready to take on the challenges of tomorrow.

Leave a Reply